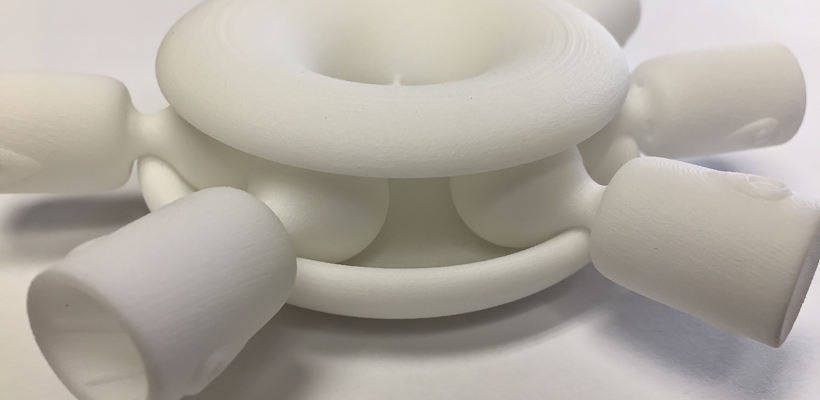

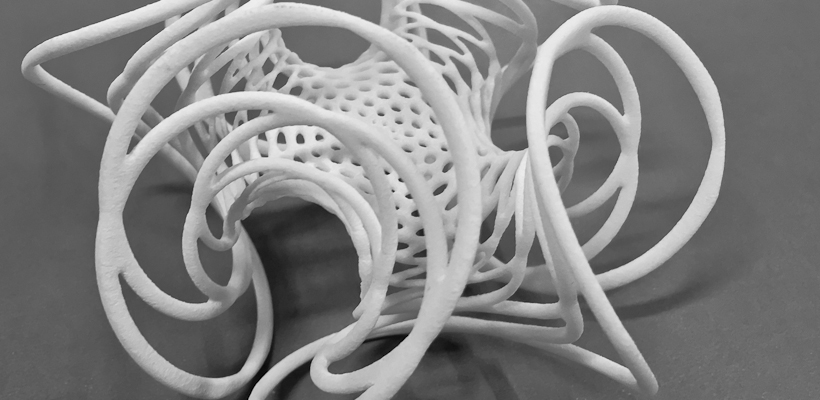

Our SLS (Selective Laser Sintering) technology uses a CO2 laser to fuse the particles of powdered nylon to create durable and robust parts. Because the laser selectively fuses only the X and Y cross-sections on the surface, the powder that is not fused becomes the support material allowing one to build complex geometries.

SLS is a great candidate for truly functional testing since nylon is a durable, high-heat, chemically-resistant, and impact-resistant thermoplastic. Geometries that cannot be molded would be excellent candidates for the SLS process. However, SLS is not ideal for model finishing because the graininess inherent in the process is pervasive through the entire part and would be quite laborious to alter.

- SLS Layer Thickness: Horizontal layering occurs at .004"

- True functional testing

- Production Nylon material

- Durable, high-heat, chemically-resistant parts

- Complex geometry

- Impact-resistant parts for repeated use (i.e. snaps/living hinges)

- Low-volume production solutions if geometry cannot be molded