SLA (Stereolithography Apparatus) technology is the oldest of the 3d printing/additive manufacturing technologies having been developed in the 1970s. Stereolithography uses a vat of liquid photopolymer resin that is cured by an ultraviolet laser. The UV laser beam scans the surface of the resin and hardens only the material corresponding to a cross section of the file thereby building the 3D part up. The required support structures for overhangs and undercuts are programmed, and later manually removed.

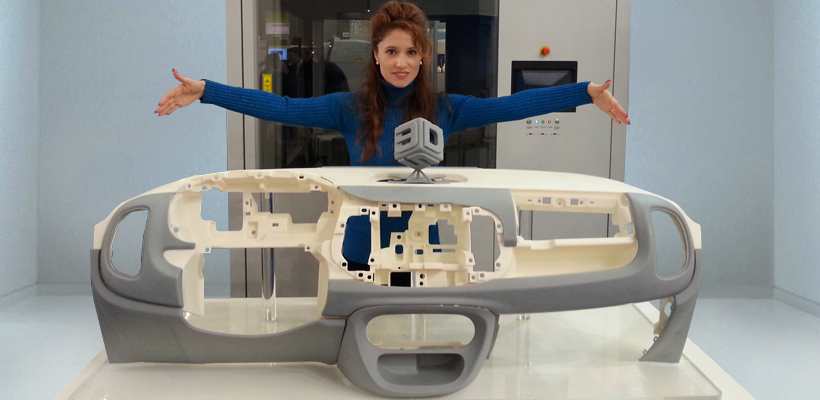

Along with tight tolerances and high resolution, our SLA equipment can handle very large parts (up to 1500 mm/59"). Building large parts in one piece increases part strength and reduces labor, as building these larger parts in pieces and assembling afterwards can be time consuming and create a weakness in the part. With the high capacity that this production system offers, you can produce low to medium batches of smaller parts at a lower per-unit cost and build massive, highly detailed pieces faster.

- Maximum Build Envelope: (W x D x H) 59 x 30 x 22 in (1500 x 750 x 550 mm)

- High Temperature

- USP Class VI

- High Impact

- ABS-like

- Polypropylene-like

- Polycarbonate-like

- Water clear / Black / White / Grey