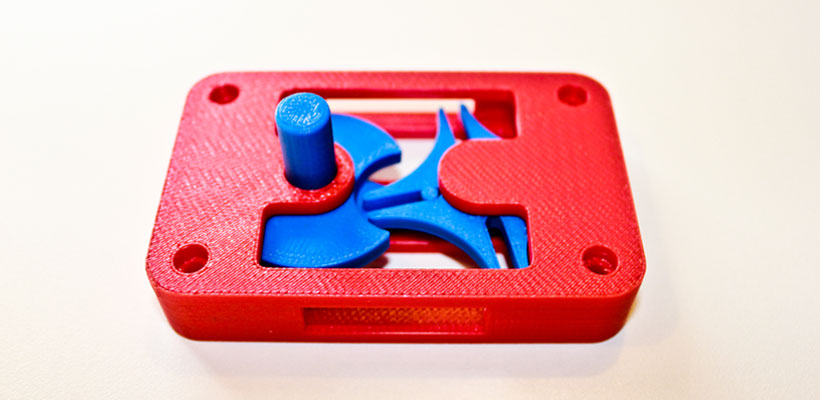

Our FDM (Fused Deposition Modeling) technology is an economical solution when prototyping large parts in low quantities.

The FDM process uses an extrusion technique to build a model layer-by-layer and can create quite durable parts. However, given the limited resolution, it is not appropriate for parts that require tight tolerances, complex geometries, or functional testing given the crack propagation that the process introduces.

FDM layer thickness: Horizontal layering occurs at two settings (.010” or .013”)

Applications:

- Jigs/Fixtures

- Thermoforming patterns

- Parts that can be hollowed out

- Form models